Research

GuD maintains close contact with universities, colleges and research institutions. Experiences and insights gained from the diversity of their many projects allows the engineers to participate in scientific progress.

Drill hole path survey

By installing micro-chips in the couplings of screw fastened drilling rods for anchors and jet grouting, the drilling rods are transformed into a chain inclinometer. This transfers readings from the drill hole path while drilling and catches deviations in the process. GuD has improved the technology with asymmetrical core drill bits, which facilitate controlled drilling.

Diameter determination of jet grouting columns

Pulse method – full-scale test

After completing several trial runs to test the principle, GuD applied the diameter determination of jet grouting columns with the pulse method to a full-scale run at a construction project in Berlin. The vibrations in an already cured column were measured while a neighbouring column was being constructed. If the location coordinates of the column centre are known, the column diameter can now be derived from a trigonometric calculation.

Joint elements for diaphragm walls

GuD has developed joint elements for diaphragm walls, deeper than 35 m, that make joints possible with high execution security, even at greater depth; this is possible because of verification of interim construction states and the structural design of the joint elements.

The joint inspector

Until recently the quality of diaphragm wall joints could not be adequately assured, because it was not technically possible to capture and evaluate the structural states and the need for rework at the joints while they were being constructed. The Joint Inspector, who can sense and measure the installation quality of joint elements and the formation of any excess concrete, can now catch faulty joint formations and get them corrected during the construction process.

The effect of construction methods on special civil engineering projects

The load-bearing capacity of the pile foundations is highly dependent on the construction method used. The effects of the construction method (vibration or diving force) on the load-bearing capacity of the driven piles has been examined in several research projects in collaboration with the TU Berlin and the University of Stuttgart using experiments and numerical calculations.

INFRASTAR

INFRASTAR is a research initiative supported by the European Union with the aim of developing knowledge, expertise and skills for the design of an optimised and reliable construction management system. INFRASTAR develops innovative solutions for the management and maintenance of infrastructure systems. Twelve young scientists receive a high-quality education in close dialog with industry and research partners. The project is part of the framework of Horizont 2020 EU-Forschungs- und Innovationsprogramm (research and innovation program) and is executed as a Marie-Sklodowska-Curie Action (MSCA) (Grant agreement No. 676139). It consists of the following:

- Five European countries: Denmark, France, Germany, Poland and Switzerland

- 12 young scientists (PHD students) from ten different countries

- Eight partners:

- IFSTTAR, Paris (F)

- EPFL, Lausanne (Ch)

- University of Aalborg (DK)

- BAM, Berlin (D)

- COWI, Copenhagen (DK)

- PHIMECA, Cournon d'Auvergne (F)

- GuD, Berlin (D)

- NeoStrain, Warsaw (P)

- Three partner organisations: BAST, EIFFAGE and VALEMO

- An Advisory Committee with six members from science and industry: University of Surrey (GB) University of Breslau (P), TNO Organisation for Applied Scientific Research, Netherlands (Niederländische Organisation für Angewandte Naturwissenschaftliche Forschung), Total S.A., German railroad (Deutsche Bahn AG), DNV-GL SE (Det Norske Veritas (Norway) and Germanischer Lloyd (Germany) specifications).

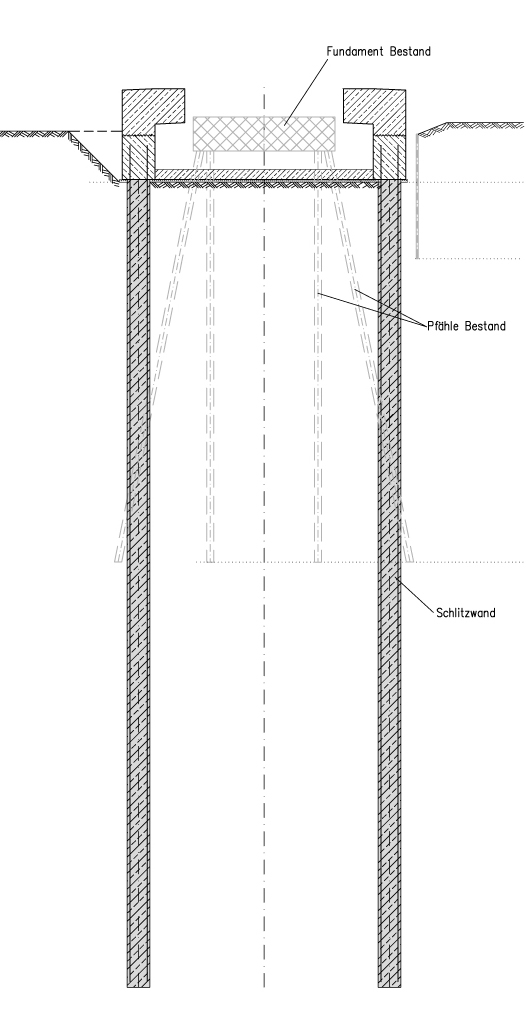

Mono Pile solutions for wind-power turbines in onshore regions

Re-powering is the umbrella term for retrofitting existing wind-power plants, which are to be retrofitted with more powerful wind turbines. A GuD proprietary, patented retrofit development in the form of pre-stressed, anchored pile walls makes it possible to geometrically create a mono pile, which carries the newly added loads of the enlarged system. The dimensions of the foundation footprint do not need to be expanded.

Cyclic degradation of pile foundations

Several large joint research projects conducted with the German Federal Institute for Materials Research and Testing (Bundesanstalt für Materialforschung und -prüfung (BAM)) resulted in new insights for lateral cyclic degradation of piles and pile load-bearing behaviour. The latter led to the development of analytical reference models, which were directly applied to the assessment of foundations for offshore projects.

Retrofit capacity increase for offshore pile foundations

A collaborative effort of the German Federal Institute for Materials Research and Testing (Bundesanstalt für Materialforschung und -prüfung (BAM)), the TU Hamburg-Harburg, and the GuD Geotechnik und Dynamik Consult GmbH is currently examining a research project on behalf of the project promoter Jülich for subsequent capacity increases to driven vs. vibration installed steel pipe driving piles.